Turning Data into Impact: Designing Sustainability Features for Manufacturing Workflows

My Role

Company:

aPriori Technologies

Team:

PM , Tech Lead, Devs

Role:

Lead Product Designer

Introduction:

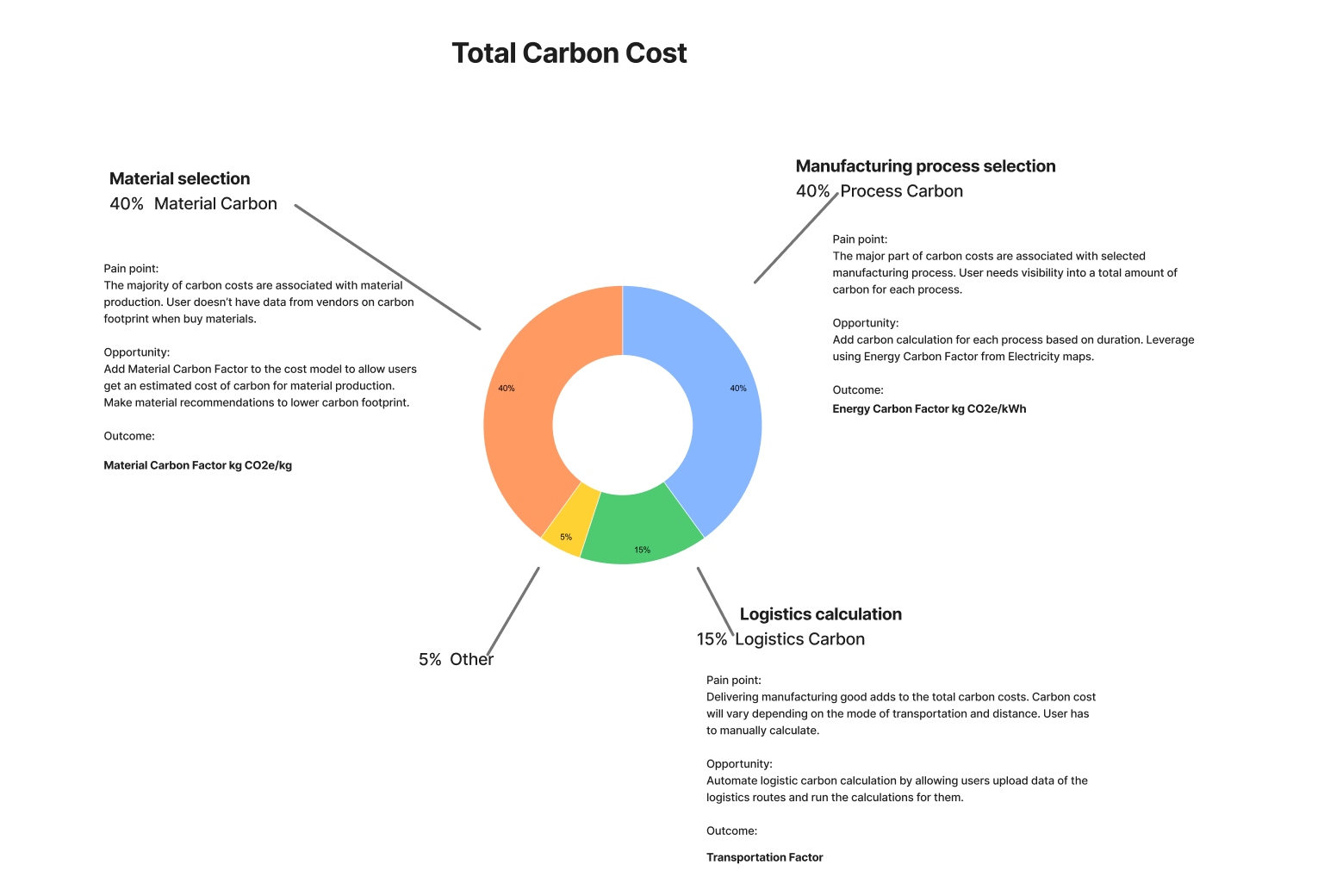

Our SaaS platform helped manufacturers and engineers simulate processes, but lacked carbon footprint and sustainability metrics, leaving customers without a full view of their design impact.

What features would add value to our customers?

The business aimed to differentiate the product and drive retention by adding carbon footprint insights to the cloud application, while users needed meaningful data to help them make informed, environmentally responsible decisions within their manufacturing processes.

PROBLEM: Product differentiation and retention

As the lead designer, I guided an early product discovery and design process that resulted in a validated summary of customer needs, a proposed set of sustainability features for the roadmap, and the launch of an MVP carbon footprint summary integrated with the current SaaS product. The new features provided procurement teams with actionable insights to make more informed, sustainable decisions and expanded product value and differentiation.

SOLUTION: Add features to help evaluate carbon footprint during manufacturing

BUSINESS IMPACT

Reduced product definition time by 30% by synthesizing user research into actionable insights.

Shipped MVP and contributed to 15% increase in upsell revenue by introducting features for sustainable manufacturing.

Helped secure 5 enterprise customers by deliveing features that addressed compliance needs.

✅

+5 enterprise customers

✅

+15 % upsell revenue

RESEARCH

I led the early product discovery phase. My contributions included: User research, Market scan, and Workshop facilitation.

User research:

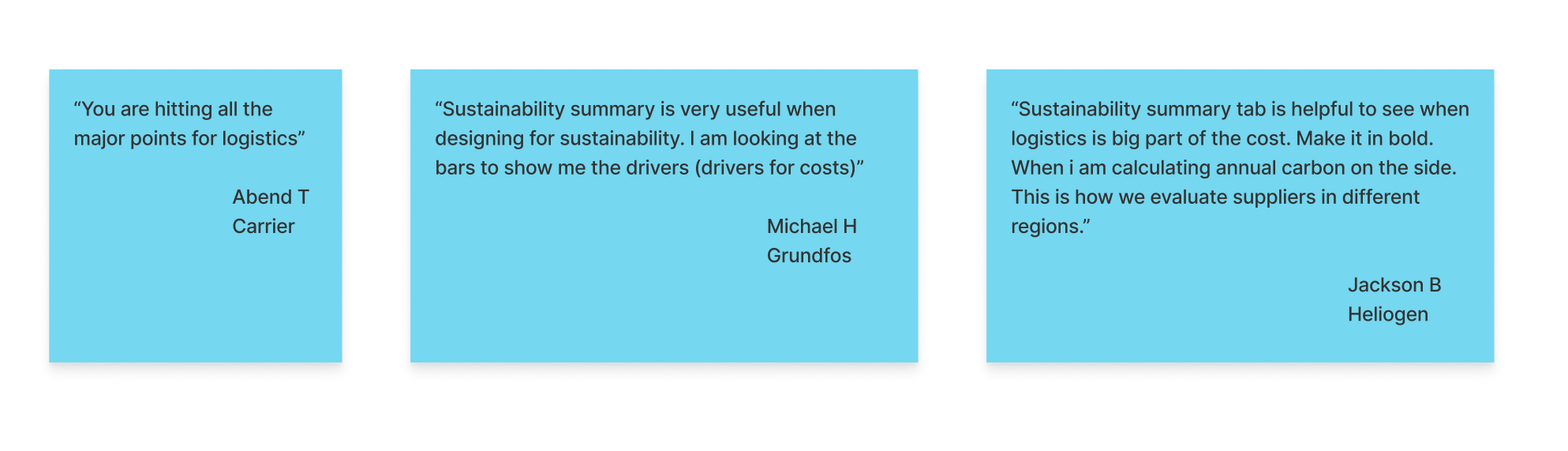

Conducted 20+ interviews with manufacturing engineers, procurement teams, and sustainability officers

Ran contextual inquiries with 3 enterprise customers to observe workflows

Synthesized insights into key pain points

Market:

Benchmarked competitors and industry standards

Identified white space

Workshop facilitation:

Ideation workshop

Defined opportunity areas

Identified opportunity area and defined new features

DESIGN EXPLORATION

Feature #1

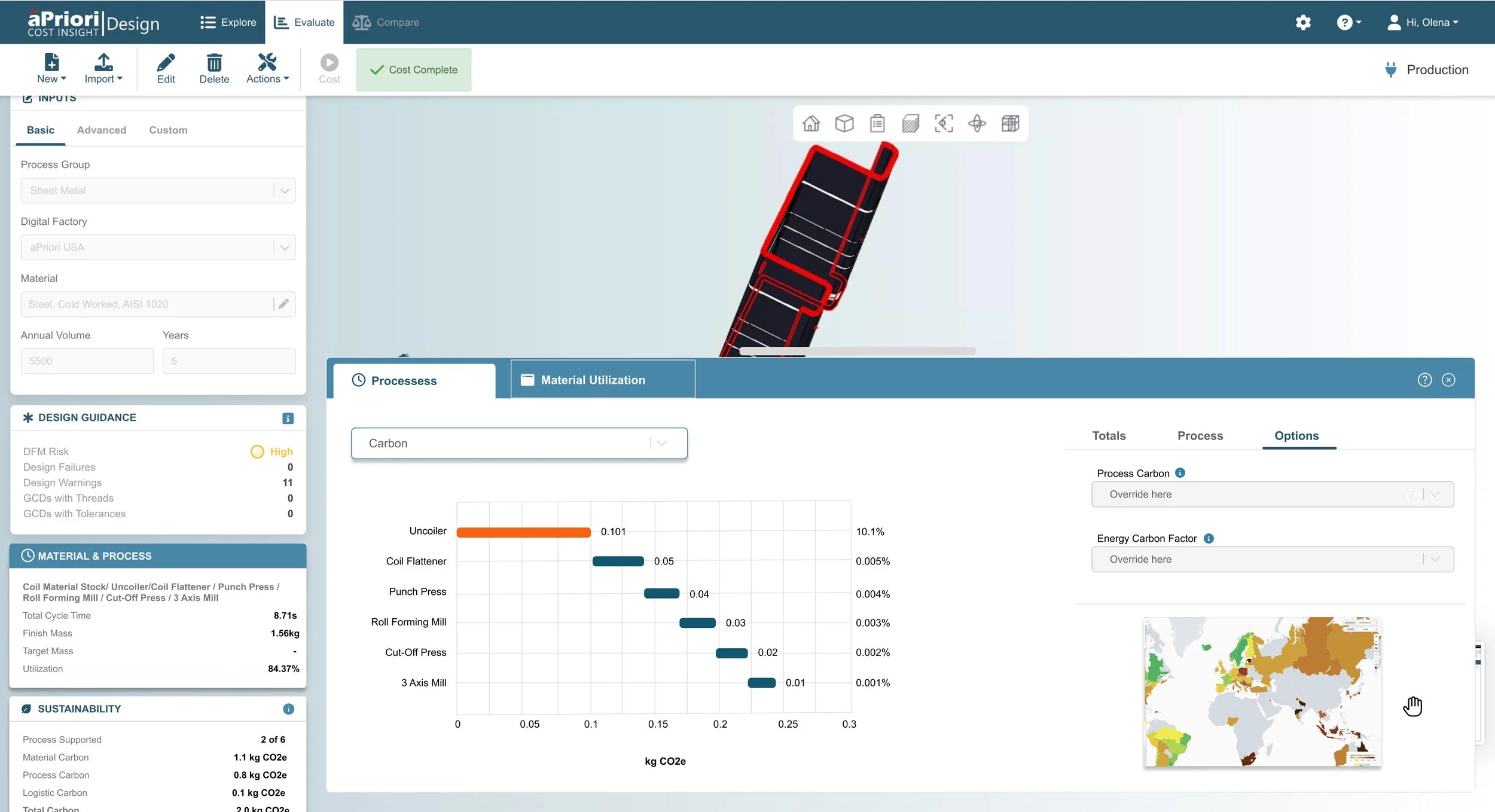

Carbon Footprint Overlay to summarize and visualize impact

Feature #2

Material Comparison Tool to optimize material selection

Feature #3

Manufacturing Process Carbon Evaluation Tool to bring transparency and evaluate alternatives

OUTCOME & IMPACT

✅

✅

✅

80% of interviewed customers confirmed a strong interest in sustainability insights

First enterprise customer adopted the carbon overlay feature, citing it as a key differentiator in their vendor selection

New features positioned the company as an early leader in sustainable manufacturing simulation software

Customer Quotes

View Other Projects